VINITECH chuyên sửa chữa biến tần, servo tại Đồng Nai, Bình Dương...

Failure type and the countermeasure

Failure

code |

Failure type |

Possible reason |

Countermeasure |

| E001 |

overcurrent

during

accelerating

process

| Improper V/F curve |

Adjust V/F curve setting adjust

manual torque boost or change to

automatic torque boost |

| Restart rotating motor |

Set speed checking restart function |

| Low power source voltage |

Check input power supply |

| Too small power of the inverter |

Choose inverter with high-power |

|

Accelerating time is too short |

Prolong accelerating time |

| |

|

| E002 |

overcurrent

during

decelerating

process

Have potential energy load or big

Inertia load |

Increase braking power of external

energy consumption braking

subassembly |

| Power of inverter is a bit small |

Choose inverter with high-power |

|

Decelerating time is too short |

Prolong decelerating time |

| |

|

| E003 |

overcurrent

during constant

speed process

Accel/Decel time is set to too

short |

Prolong accelerating decelerating

time properly |

| low power source voltage |

Check input power supply |

| Power of inverter is a bit small |

Choose inverter with high-power |

|

Load change suddenly or

Have unwonted phenomena |

Check or reduce break of the load |

| |

|

| E004 |

overvoltage

during

accelerating

process

| Accel time is set to too short |

Prolong accelerating time properly |

| Restart rotating motor |

Set speed checking restart function |

|

Unwonted input voltage |

Check input power supply |

| |

|

| E005 |

overvoltage

during

decelerating

process

Have potential energy load or big

inertia load |

Increase braking power of external

energy consumption braking

subassembly |

|

Decelerating time is too short |

Prolong decelerating time |

| |

|

| E006 |

Overvoltage

during constant

speed process

| |

| Input voltage change abnormally |

Assemble reactor |

| Load inertia is a bit big |

Use energy consumption

subassembly |

Accel/Decel time is set to too

short |

Prolong accelerating decelerating

time properly |

|

Unwonted input voltage |

Check input power supply |

| |

|

| E007 |

Inverter control

power supply

overvoltage |

Unwonted input voltage |

Check input power supply or look for

service |

| E008 |

Inverter

overload

| DC injection braking is too big |

Reduce DC injection braking

current prolong braking time |

| improper V/F curve |

Adjust V/F curve and torque boost |

| Restart rotating motor |

Set speed checking restart function |

| power source voltage is too low |

check power source voltage |

| Load is too big |

Choose inverter with high-power |

| E009 |

Motor overload |

improper V/F curve |

Adjust V/F curve and torque boost |

| power source voltage is too low |

check power source voltage |

General motor run at low speed

with big load |

Can choose frequency conversion

motor for long time low speed run |

motor overload protection factor

set incorrectly |

to set motor overload protection

factor correctly |

motor blocked up or load change

too suddenly and quickly |

Check the load |

|

Accel time is set to too short |

Prolong accelerating time |

| |

|

| E010 |

inverter over

heating

| Ambient temperature is too high |

Improve ventilation condition, lower

carrier frequency |

| Fan damaged |

Replace the fan |

|

Air-path blocked |

T veoncti lelaatrioai nrc -poantdi h toion r improve |

| |

|

| E011 |

reserved |

reserved |

reserved |

| E012 |

reserved |

reserved |

reserved |

| E013 |

Inverting

module

protection

phase to phase short circuit or

earthing short circuit of output 3

phase |

wiring again |

| Air-path blocked or fan damaged |

To clear air-path or replace the fan |

| Ambient temperature is too high |

Lower ambient temperature |

Connecting wire or insert on

control board loose |

Check and connect the wire again |

Unwonted current wave caused

by missing output phase etc. |

Check wiring |

Assistant power supply damaged

and drive voltage lacking |

Look for service from manufacturer

or agent |

| Unwonted control board |

Look for service from manufacturer

or agent |

|

Transient overcurrent of the

inverter |

Refer to countermeasure for

overcurrent |

| |

|

| E014 |

external device

failure

Use sudden stop key

under condition of stall |

Set running parameter correctly |

Sudden stop terminal for external

failure closed |

Open external failure terminal after

external failure is settled |

|

use sudden stop key in

non-keypad run mode |

Look up operation mode |

| |

|

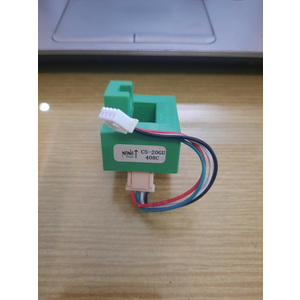

| E015 |

current

detecting circuit

failure

| Assistant power supply damaged |

Look for service from manufacturer

or agent |

| Hall component damaged |

Look for service from manufacturer

or agent |

| Unwonted amplifying circuit |

Look for service from manufacturer

or agent |

|

Connecting wire or insert on

control board loose |

Check and connect the wire again |

| |

|

| E016 |

RS485

communication

failure

| Serial port communication error |

press key to reset

look for service |

Failure warning parameter set

improperly |

Modify F2.16, F2.17 |

| Upper device doesn’t work |

C ishcec orkreict f upper device work and wiring |

|

Baud rate set improperly |

set Baud rate properly |

| |

|

| |

|

| E017 |

reserved |

reserved |

reserved |

| E018 |

reserved |

reserved |

reserved |

| E019 |

Under voltage

failure

Main control DSP read and write

wrongly |

Reset by the key-press, look for

service |

|

Under voltage |

check spot input voltage |

| E020 |

System

disturbance |

Serious disturbance |

| |

|

| E021 |

reserved |

reserved |

reserved |

| E022 |

reserved |

reserved |

reserved |

| E023 |

E2PROM read

and write

wrongly |

Mistake take place when read or

write control parameter |

Reset by pressing

Look for service from manufacturer

or agent |

P.

OFF |

Under

voltage failure |

Under voltage |

Check spot input voltage |